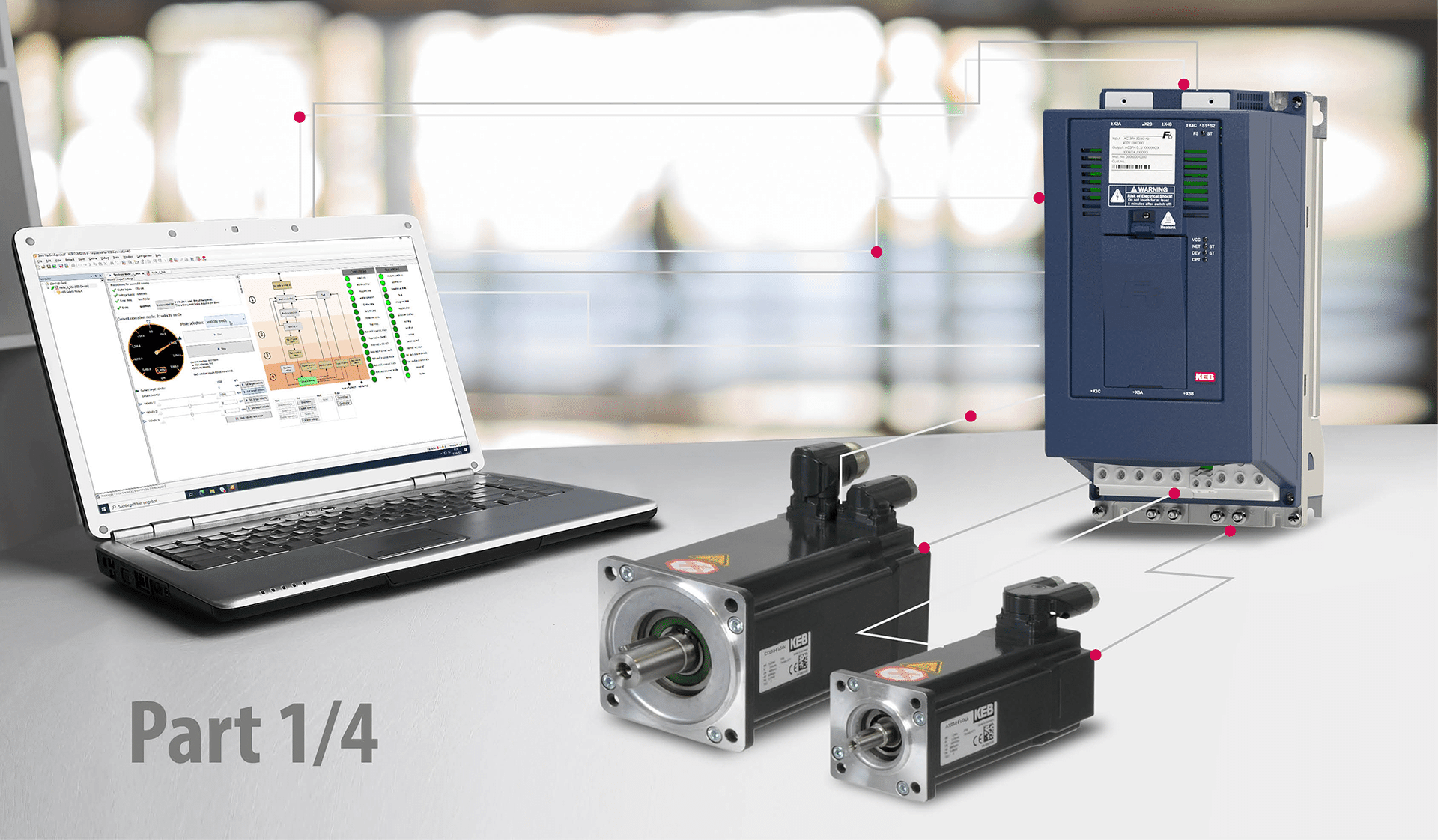

TechTuesday

KEB’S WEB SEMINARS

KEB Automation keeps you informed about developments and solutions in the areas of drive technology and automation. Find out which new opportunities exist to help you carry out your tasks. From control and drive technology to motors, brakes and clutches: discover KEB’s “TechTuesday” webinars. You can find all the latest topics and dates here. Simply register via the links. Use the chat function to ask KEB’s experts questions directly.

An overview of technologies for drives, controls and more

- Free participation

- The latest topics and trends

- High practical relevance

- Information – short and compact

- Direct contact with your counterparts

TOPICS AND DATES