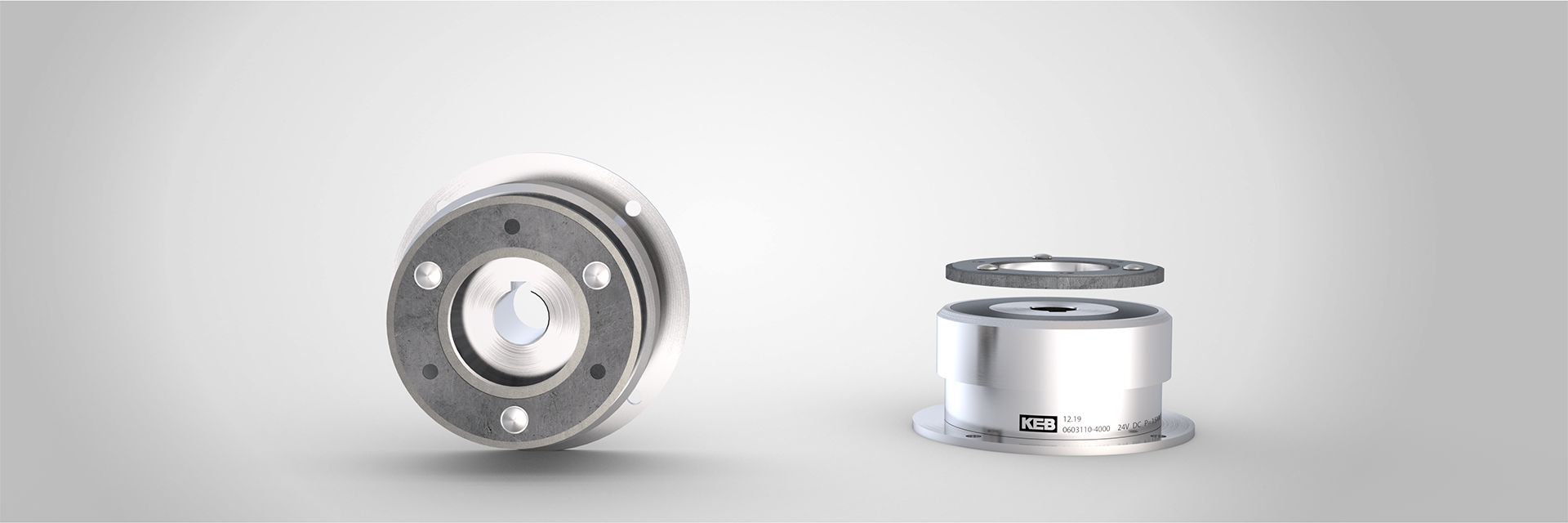

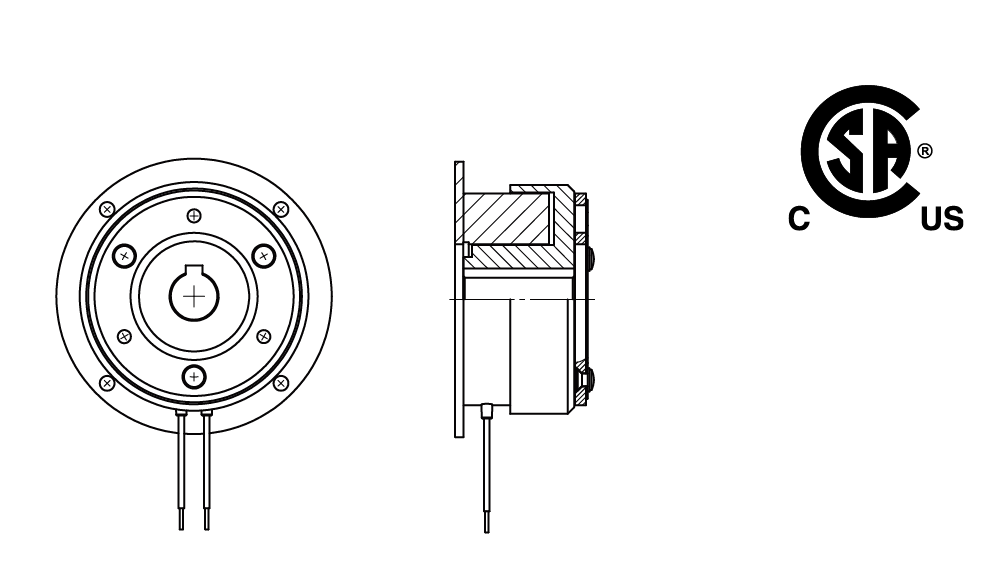

ELECTROMAGNETIC CLUTCH

COMBINORM C

The operating current clutch COMBINORM C provides clutch engagement when electrically powered. As a result it enables particularly simple controlled switching on and off of functional parts. The electromagnetic clutch is suitable for reliable positioning and torque transmission of switchable shaft connections in synchronised processes.

The electromagnetic clutch has a torque range of 0.5 Nm to 1,250 Nm.

Highlights

- 13 sizes

- Short switching times

- Positioning accuracy and functional reliability

- Designed for S1 operation or 100 % duty cycle

- ISO class B in accordance with VDE 0580

- Wide temperature and voltage range

- Continuously adjustable torque

- Standard voltage 24V

Options

If it is intended that the end products will also be used on the Canadian or American market, the relevant certification can be obtained for the COMBINORM C.

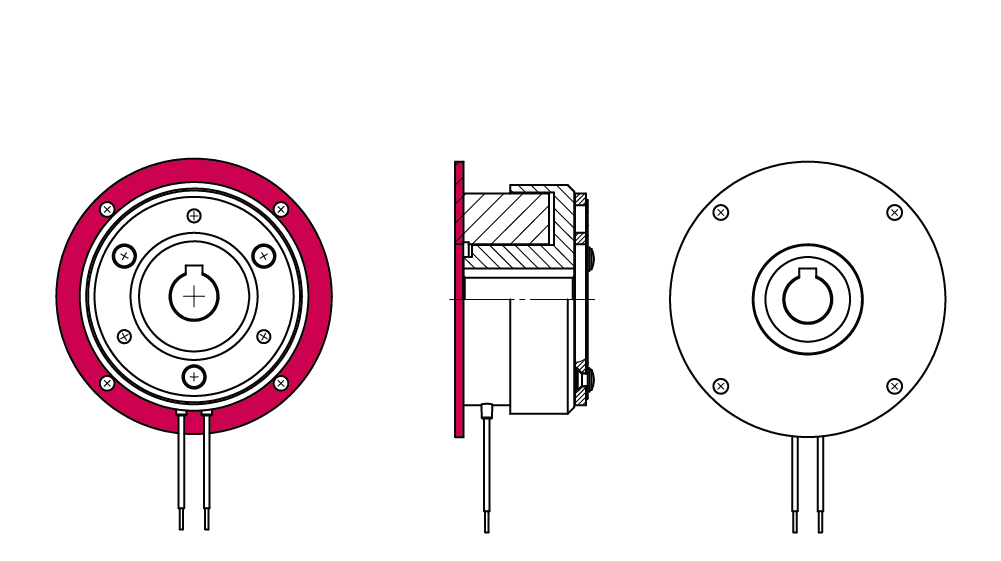

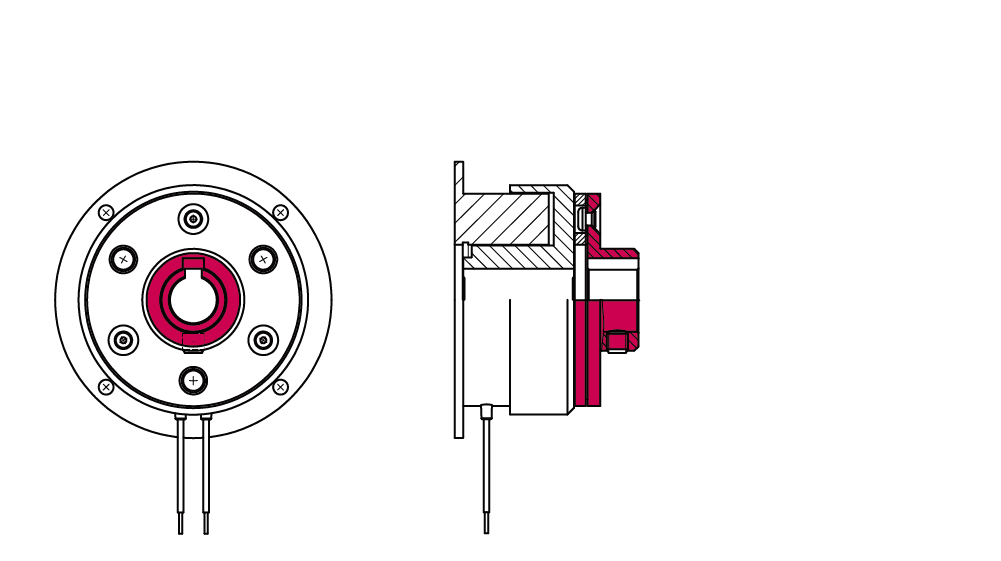

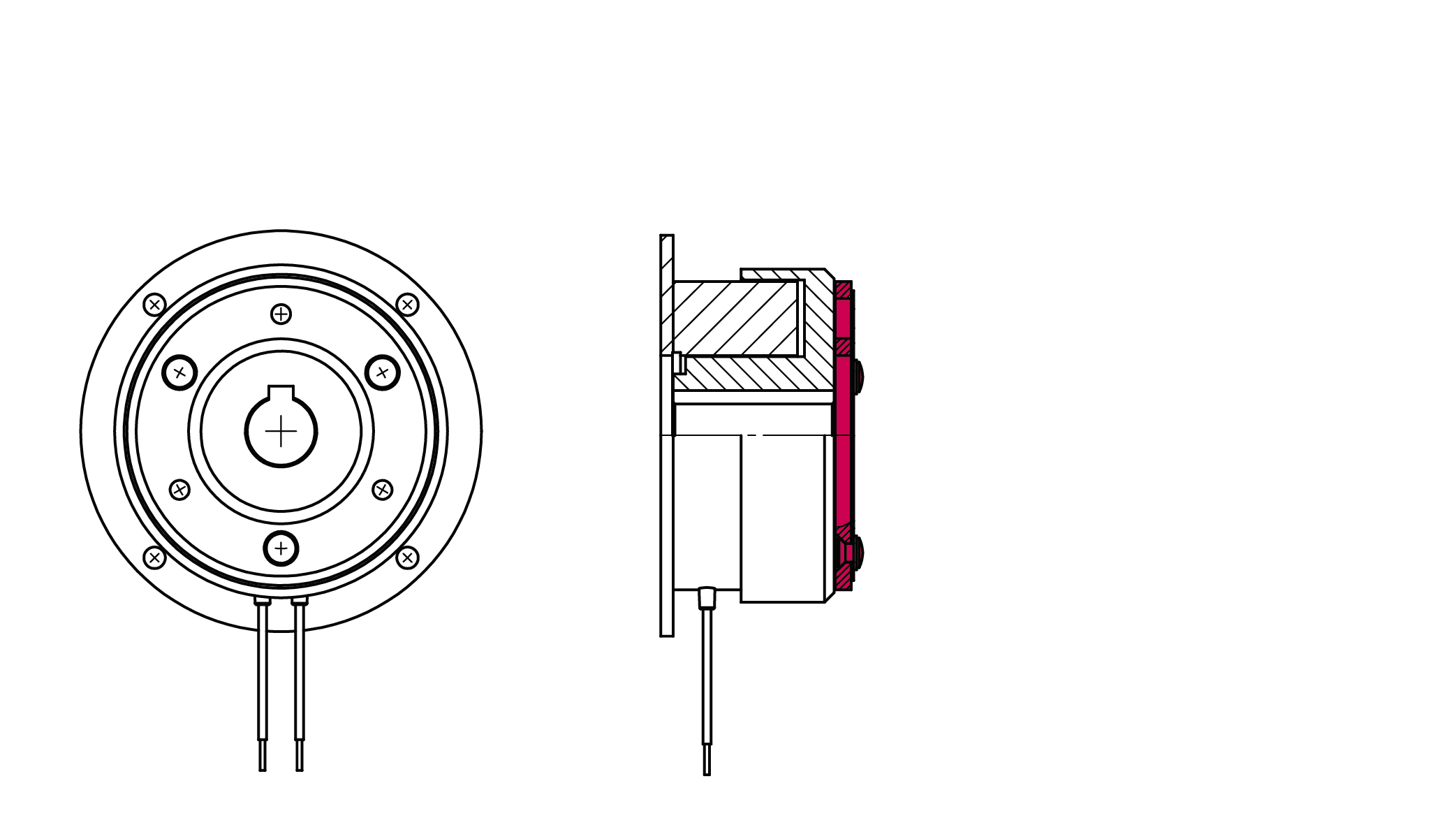

If the COMBINORM C has a shaft-mounted design, the rotor is fastened to one of the two shafts to be coupled. In this case, the magnetic part is mounted on the rotor and is prevented from rotating either by a flanged connection or by a torque bracket. In this case, the armature part is mounted directly on the mounting surface, e.g. the pinion, belt pulley or shaft end to be coupled.

If the application requires a modified voltage, a customised coil with the corresponding voltage can be realised in the internal production process.

If the assembly process of the brake has to be simplified, our products can be equipped with ready-to-connect cables with plugs, contacts or even wire end ferrules.

A factory certificate 2.1 according to DIN EN 10204 that the delivered products comply with the agreements at the time of order can be provided at the customer's request. This certificate is issued based on non-specific testing. Also, an acceptance test certificate 3.1 according to DIN EN 10204 can be issued at the customer's request. In this case, the confirmation is given with the results of specific tests, such as the torque test.

TECHNISCHE DATEN

| Size | Rated torque M2 [Nm] | Standard power [W] | Diameter [mm] | max. Rotor bore [mm] | max. Hub bore [mm] |

| 01 | 0.5 | 6 | 39 | 6 | 6 |

| 02 | 0.75 | 6 | 45 | 8 | 8 |

| 03 | 1.5 | 8 | 54 | 10 | 10 |

| 05 | 3 | 10 | 65 | 17 | 15 |

| 06 | 7 | 15 | 80 | 20 | 18 |

| 07 | 15 | 20 | 100 | 25 | 22 |

| 08 | 30 | 28 | 125 | 30 | 30 |

| 09 | 65 | 35 | 150 | 35 | 35 |

| 10 | 130 | 50 | 190 | 50 | 45 |

| 11 | 250 | 68 | 230 | 65 | 60 |

| 12* | 500 | 85 | 290 | 80 | 70 |

| 13* | 750 | on request | 355 | 90 | 90 |

| 14* | 1250 | on request | 440 | on request | on request |

Standard voltage: 24 V | Special voltage: on request

Documentation

In use in these areas of application

MEDICAL TECHNOLOGY

Precision, safety and repeatability are essential in medical technology. This requires solutions that are as reliably produced as the work in the healthcare industry demands. With know-how and established products, KEB has been meeting the high demands in medical technology for decades.

DOOR AND GATE OPERATORS

KEB provides optimal solutions for door and gate operators with an extensive product portfolio. From industrial doors such as fire doors to sectional, high-speed or roller doors and access technology. Safety, functionality and complex operating processes are always the focus.

WOODWORKING MACHINERY

KEB’s variable-speed frequency inverters create the perfect basis for treating and processing the renewable and carbon-neutral raw material, wood – in complete safety.

E-MOBILITY

With innovative solutions, KEB enables the electronic operation of auxiliary systems in commercial vehicles and mobile machinery, thereby reducing emissions.

ROBOTICS AND AUTOMATION

In robotics, compactness, repeatability and positioning accuracy are important. Our products meet these criteria precisely and are characterised by their high quality and flexibility. Standard and customised solutions are used by robotics customers all over the world.

PACKAGING & FOOD PROCESSING

KEB provides the food processing and packaging industry with robust components that are suitable for use in harsh environments.

AGRICULTURAL, MINING AND MUNICIPAL MACHINERY

Smooth operation, even over long periods of time, requires durable and robust components. These should nevertheless operate according to today's Industry 4.0 standards. Intelligent and robust products from KEB ensure operation in the demanding applications.