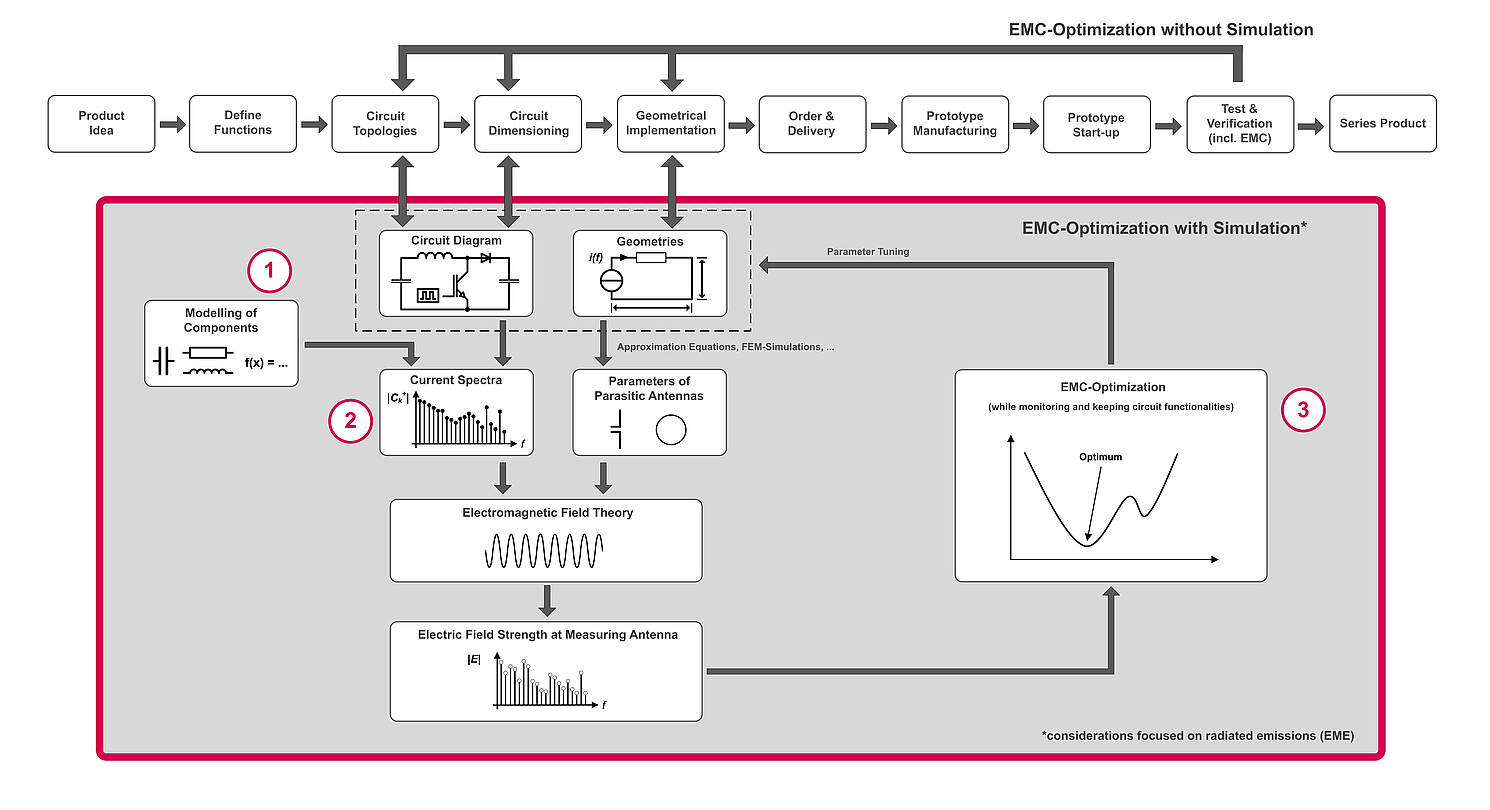

Three steps to EMC optimisation

Simulation methodology offers advantages for product development

In addition to the function of an electrical circuit, electromagnetic compatibility (EMC) and especially electromagnetic emissions (EME) are important aspects in a product development process. At the EPE'22 ECCE Europe conference in Hanover, KEB Automation presented ways to optimise EMC by simulations. This makes development processes more time- and cost-efficient.

At the EPE trade fair booth, KEB Automation gave an overview of EMC simulation methodology as part of its basic research. Prototype-based iteration loops can easily lead to time-consuming and costly design processes. This is because design changes often lead to repeatedly occurring ordering and delivery times, prototype production and prototype commissioning. Only then can testing and verification take place and product certification be completed.

VIRTUELLE TESTS FÜR DIE PRODUKTOPTIMIERUNG

Against this background, simulations and virtual tests are preferred for product optimisation. Time-domain simulations are suitable for optimising electromagnetic compatibility while monitoring and preserving circuit functions. To perform the virtual tests, models of electrical components must be built as a first step if they are not available or insufficient for simulating function and EME as part of EMC.

Many circuit parts and components can be modelled by conventional methods and are mainly based on measurements with network analysers, LCR meters and oscilloscopes. After the measurements, the behaviour of the components is represented by equivalent circuits and mathematical functions. However, some components are internally inaccessible and difficult to model. Conventional modelling methods are not suitable here. The remedy is grey box modelling – a topic presented by Jan-Philipp Roche, basic developer in the electronics development department at KEB, at a lecture during the EPE'22 conference.

Grey box modelling

Grey box modelling is the focus topic of an ongoing doctoral project that Jan-Philipp Roche is working on with the support of KEB Automation. The aim is to combine the advantages of white and black box models. Prior knowledge and physical findings from white-box models can be implemented, very complex or unknown behaviour can be trained to neural networks.

In addition to the electrical components of the circuits, parasitic components are also modelled using conventional methods. These include EMC-relevant couplings and parasitic antennas, but also common parasitic elements such as stray inductances.

Carrying out EMC-relevant tests

When the modelling is complete, simulations can be run in the second step and virtual tests can be performed based in these simulations. The electric field strength at the measuring antenna is an example of such an EMC-relevant test. LTspice is used here as the main simulation tool to simulate the corresponding current spectra. The results of the virtual test are the feedback for the optimisation loop. This represents the third step by which EMC (and especially EME) can be efficiently optimised compared to prototype-based design iterations.