Filter for high frequency: Minimized power dissipation

What power amplifier topologies alone cannot achieve

Highly efficient machine concepts for Turbo Blower or in machining with CNC spindles – made possible by new drive controllers and filter concepts for high frequency (HF) applications. The aim is to increase performance and protect the motor winding at output frequencies of up to 2,000 Hz.

“For industrial high-speed applications, we have developed particularly powerful drive controllers with which our customers can optimally operate all common high-frequency spindles and high-speed motor types,” explains Fabian Fischer, Team leader Application Sales.

The associated motor filter technology is an important part of the drive package. HF motor chokes, input/output filters and sinusoidal filters based on the latest core materials ensure the long-lasting operation of CNC main spindles or high-speed compressors.

Turbo Blower

Motor choke and sinusoidal filter

© Alfred Jäger GmbH - High Speed Spindel

© Alfred Jäger GmbH - High Speed Spindel

Advantage: motor choke

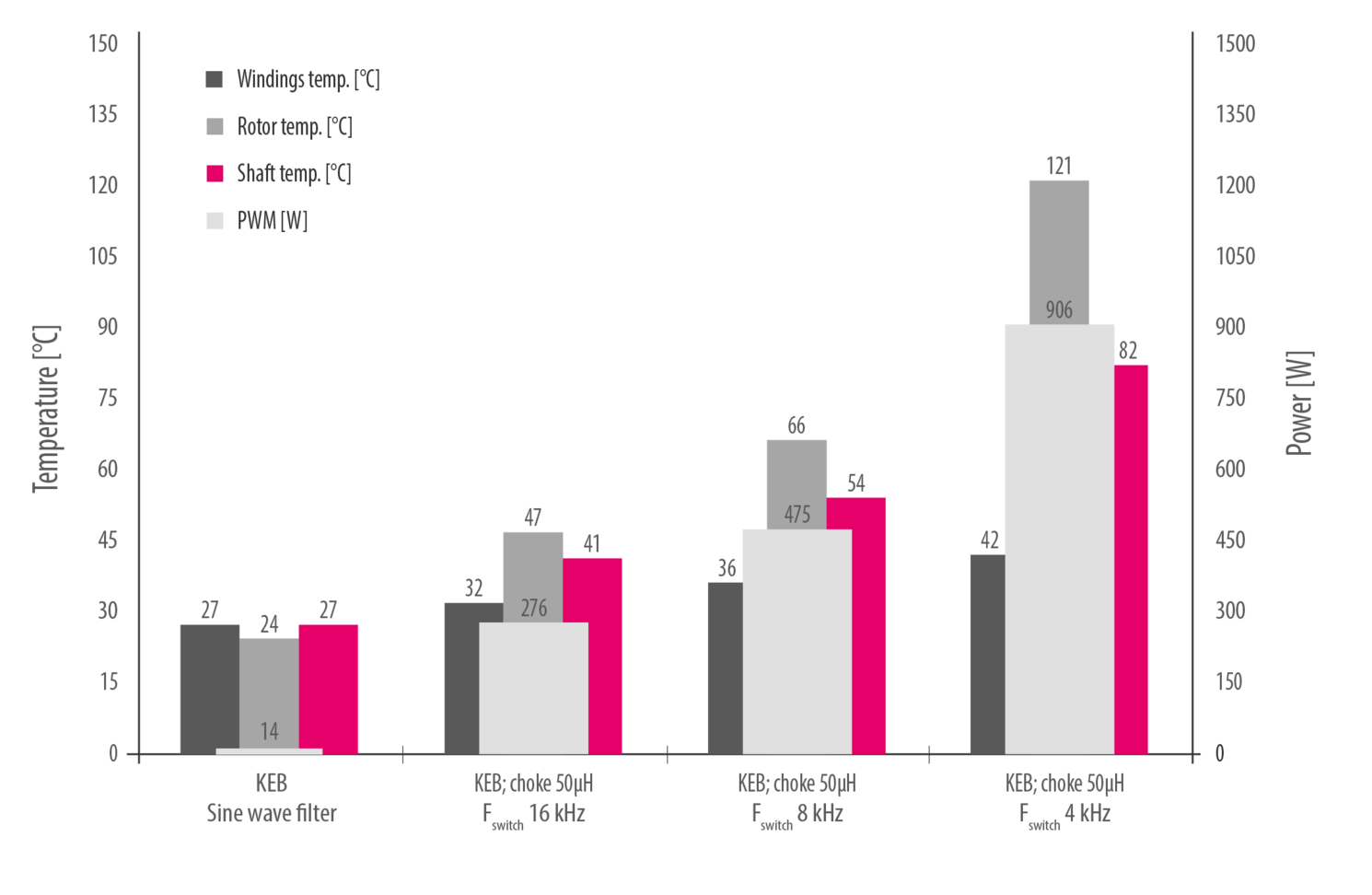

The two main features are based on the winding protection and the stabilization of the thermal balance of the HF motors. “By using a specially designed HF motor choke, both the voltage level in the winding and the rate of voltage rise (dU/dt) can be reduced to below 500 V/µs”, says Fischer. Both are main criteria for the lifetime of the insulation. In addition, there is a noticeable reduction in the high frequency spectrum and thus an improvement in the power loss balance in the motor.

Advantage: sinusoidal filter

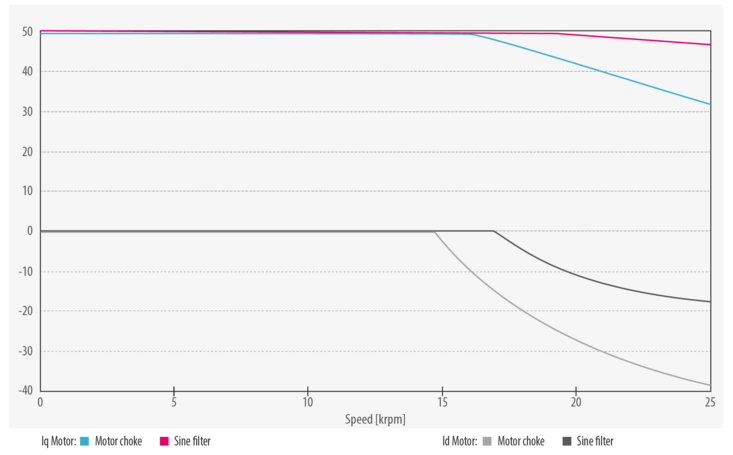

For thermally very sensitive systems – such as air-bearing spindles or the electromagnetic bearing of the rotor in blower motors – both the current and the phase voltage must be reduced to the torque-forming fundamental frequency.This requires the use of a sine filter (diagram "Comparison – switching frequency and filter technology").

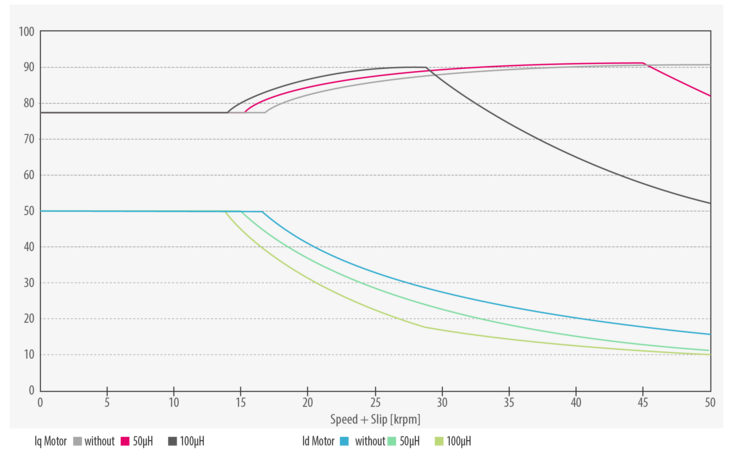

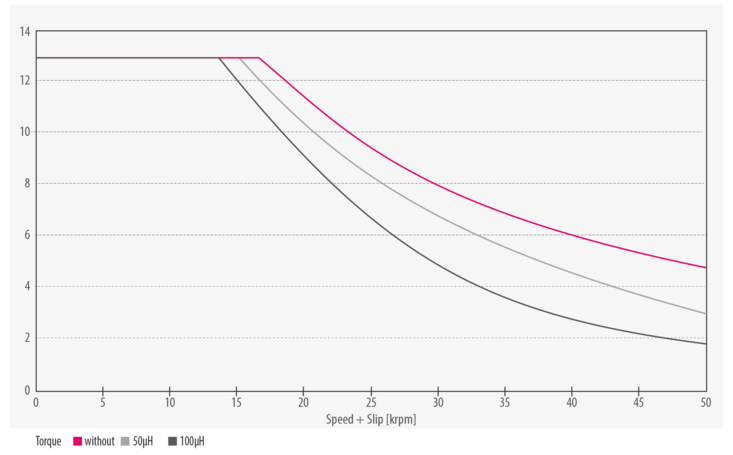

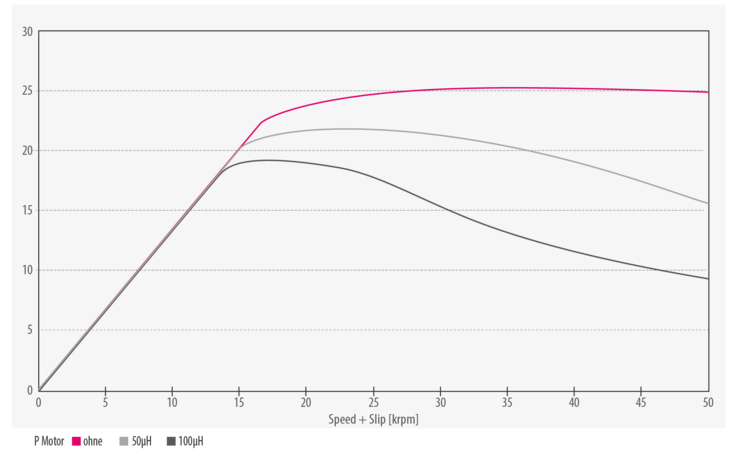

By using a motor filter, the physical properties and thus the equivalent circuit diagram of the motor is significantly changed due to the filter's own inductance (diagram: influence of motor chokes with different inductance on torque and shaft power of an asynchronous motor). Fischer says: “In order to adjust the components in the system in such a way that control dynamics, torque and shaft power on the motor side are not significantly reduced, we start at two points: Firstly through our own filter development, production and EMC test environment and secondly through additional control routines in the drive controllers.”

Asynchronous motor – without and with different types of motor chokes

Influence of motor chokes with different inductance on torque and shaft power of an asynchronous motor

Influence of motor chokes with different inductance on torque and shaft power of an asynchronous motor

Influence of motor chokes with different inductance on torque and shaft power of an asynchronous motor

Resonance free operation

For correct operation of the sine filter, the output circuit can be checked for the natural frequency and the filter-internal components can be dimensioned for resonance-free operation. For large series, it is possible to tune an application-specific sine filter to the operating point of the customer's machine.

“Here, the power loss balance can be optimized in a way that would not be possible with any currently known modulation method and none of the common power stage topologies on the inverter side”, explains Fischer.

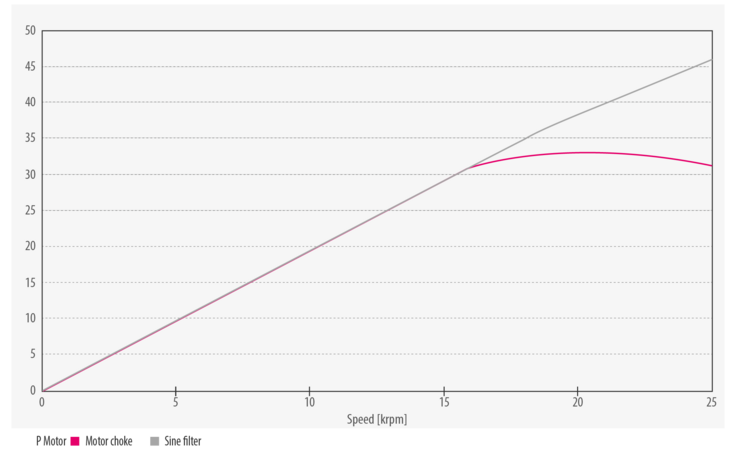

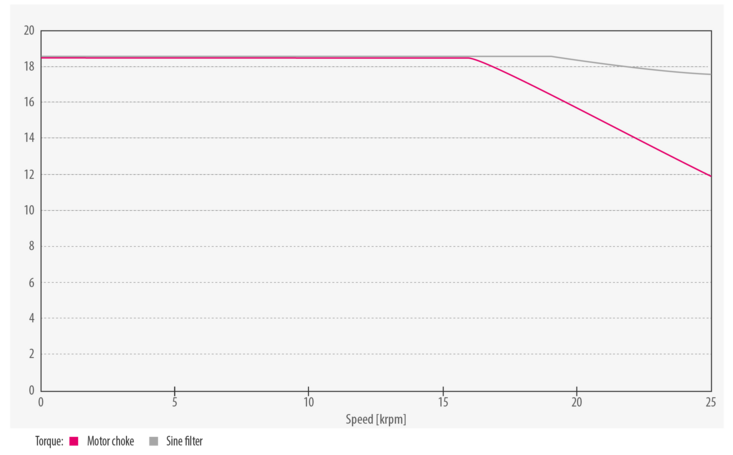

In addition, the motor / sinusoidal filter output network can be adjusted in such a way that the power loss balance is improved by increasing the voltage at the motor terminals, respectively an increase in power at the motor shaft is achieved (diagram: increase of a synchronous motors performance with sinusoidal filter).

The COMBIVERT F6 and S6 drive controllers feature software notch filters which generate resonance-free modulation for all speed-controlled operating modes, whether with or without encoder.

Synchronus motor - with/without sine filter

Increase of a synchronous motors performance with sinusoidal filter

Increase of a synchronous motors performance with sinusoidal filter